Tuna Terminal

Tuna Terminal handles all types of dry bulk cargo including coal, fertilizers, minerals, industrial salt and agriculture products. The Terminal has fully mechanized, highly automated dry bulk cargo handling facility with a fully mechanized closed warehouse to handle agro and fertilizer imports. Situated in the vicinity of Kandla port, Tuna has an all-weather berthing facility with a deep draft. It also enjoys proximity to to the Central and North-west hinterland of India.

Read more

Quick Links

Container Tracking

Cargo Services

With deep draft berths and multipurpose terminals, the port efficiently handles the largest bulk carriers in the world. The port has covered and open storage areas with enormous capacity. Excellent cargo evacuation and receiving infrastructure, support smooth cargo movement in and out of the port. Expertise in successfully handling over-sized and overweight project cargo.

- Expert at handling diversified cargo like

Fertilizer

Agri

Mines & Minerals

Steel & Project Cargo

- Superior discharge rates - Fast turnaround.

- Single Window System: APSEZ manages all port operations including berthing, stevedoring, back-up handling and dispatch of cargo

- Dedicated berth with high-speed conveyer system from Jetty till warehouse

- Installed high-speed mechanized bagging system for quality packaging and faster turnaround of rakes and trucks

- Installed world-class automated neem coating facility for Urea handling

- The terminal can handle these products in bulk using the specialized equipment ensuring efficient operations and eliminating cargo spillages.

With deep draft berths and multipurpose terminals, the port efficiently handles the largest bulk carriers in the world. The port has covered and open storage areas with enormous capacity. Excellent cargo evacuation and receiving infrastructure, support smooth cargo movement in and out of the port. Expertise in successfully handling over-sized and overweight project cargo.

- Expert at handling diversified cargo like

Fertilizer

Agri

Mines & Minerals

Steel & Project Cargo

- Superior discharge rates - Fast turnaround.

- Single Window System: APSEZ manages all port operations including berthing, stevedoring, back-up handling and dispatch of cargo

- Dedicated berth with high-speed conveyer system from Jetty till warehouse

- Installed high-speed mechanized bagging system for quality packaging and faster turnaround of rakes and trucks

- Installed world-class automated neem coating facility for Urea handling

- The terminal can handle these products in bulk using the specialized equipment ensuring efficient operations and eliminating cargo spillages.

-

TunaTuna, Gujarat

Tuna

Terminal Service Warehousing Bonded Domestic Rail Transportation EXIM Domestic Road Transportation EXIM Domestic Auto Logistics

Infrastructure

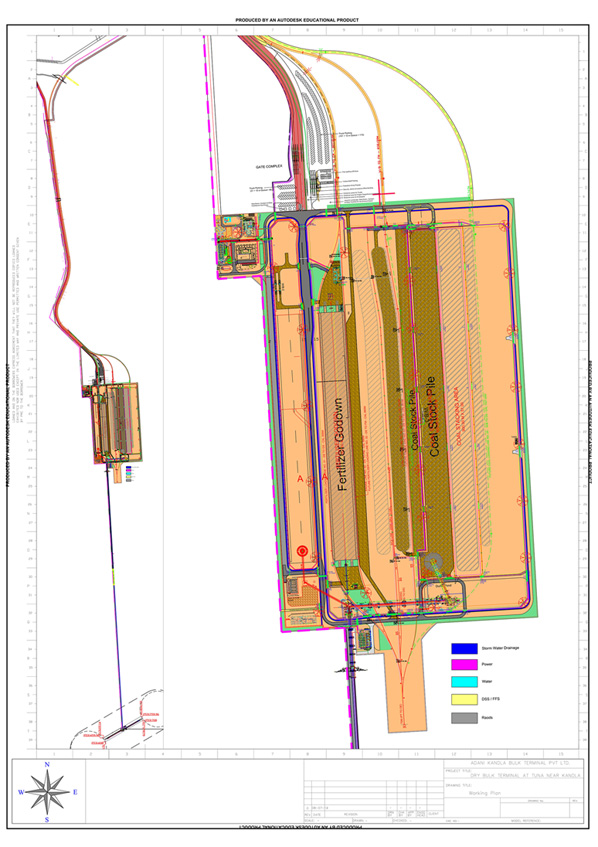

Tuna Terminal has vast infrastructures which handles multiple types of Cargo. With deep draft berths and multipurpose terminals, the port efficiently handles the largest bulk carriers in the world. The port has covered and open storage areas with enormous capacity. Excellent cargo evacuation and receiving infrastructure support smooth cargo movement in and out of the port.

The terminal has adequate closed godown and open yards for storage of large volumes of cargo. The closed godown can store more than 170,000 MT of cargo. Open yards, with a total area of 13.12 Hectare.

Support infrastructure with 4 Truck weigh bridges and 2 in-motion weigh bridge for Rake movement.

Cargo can be received and evacuated by road and rail.

Tuna can handle 4 rakes per day. It has separate sidings for agri, fertilizer and coal cargo. The port has good road connectivity to NH – 8A allowing fast and easy movement of cargo from / to the port.

Tuna Terminal has deep drafts, all weather berthing facilities. The berths at the port are capable of handling mini cape size vessels.

The Terminal is an All Weather Port; with no loss of operational days this Terminal is the choice for trade. Tuna Port also boasts of a superior support infrastructure and assets. These ensure a smooth and uninterrupted operation at the port.

Rail

Tuna Terminal rail link is connected to national rail network and hence cargo can be handled for and from any location in India. Superior rail infrastructure at the Terminal and nation-wide connectivity eliminates multiple handling and results in reduced handling losses.

Road

Tuna Terminal is well connected by National Highway No. 8 A.

The terminal infrastructure at Tuna is capable of simultaneously handling multiple vessels. A set of high capacity Liebherr Cranes and Hoppers ensure quick discharge of vessels.

A large fleet of support equipment such as excavators, pay loaders, dumpers and mechanized cleaning machine ensures uninterrupted and smooth operations across entire terminal. Additionally, the Terminal has fully integrated high speed conveyors system for smooth and fast transit of cargo to and fro port.

The terminal has adequate closed godown and open yards for storage of large volumes of cargo. The closed godown can store more than 170,000 MT of cargo. Open yards, with a total area of 13.12 Hectare.

Support infrastructure with 4 Truck weigh bridges and 2 in-motion weigh bridge for Rake movement.

Cargo can be received and evacuated by road and rail.

Tuna can handle 4 rakes per day. It has separate sidings for agri, fertilizer and coal cargo. The port has good road connectivity to NH – 8A allowing fast and easy movement of cargo from / to the port.

Tuna Terminal has deep drafts, all weather berthing facilities. The berths at the port are capable of handling mini cape size vessels.

The Terminal is an All Weather Port; with no loss of operational days this Terminal is the choice for trade. Tuna Port also boasts of a superior support infrastructure and assets. These ensure a smooth and uninterrupted operation at the port.

Rail

Tuna Terminal rail link is connected to national rail network and hence cargo can be handled for and from any location in India. Superior rail infrastructure at the Terminal and nation-wide connectivity eliminates multiple handling and results in reduced handling losses.

Road

Tuna Terminal is well connected by National Highway No. 8 A.

The terminal infrastructure at Tuna is capable of simultaneously handling multiple vessels. A set of high capacity Liebherr Cranes and Hoppers ensure quick discharge of vessels.

A large fleet of support equipment such as excavators, pay loaders, dumpers and mechanized cleaning machine ensures uninterrupted and smooth operations across entire terminal. Additionally, the Terminal has fully integrated high speed conveyors system for smooth and fast transit of cargo to and fro port.